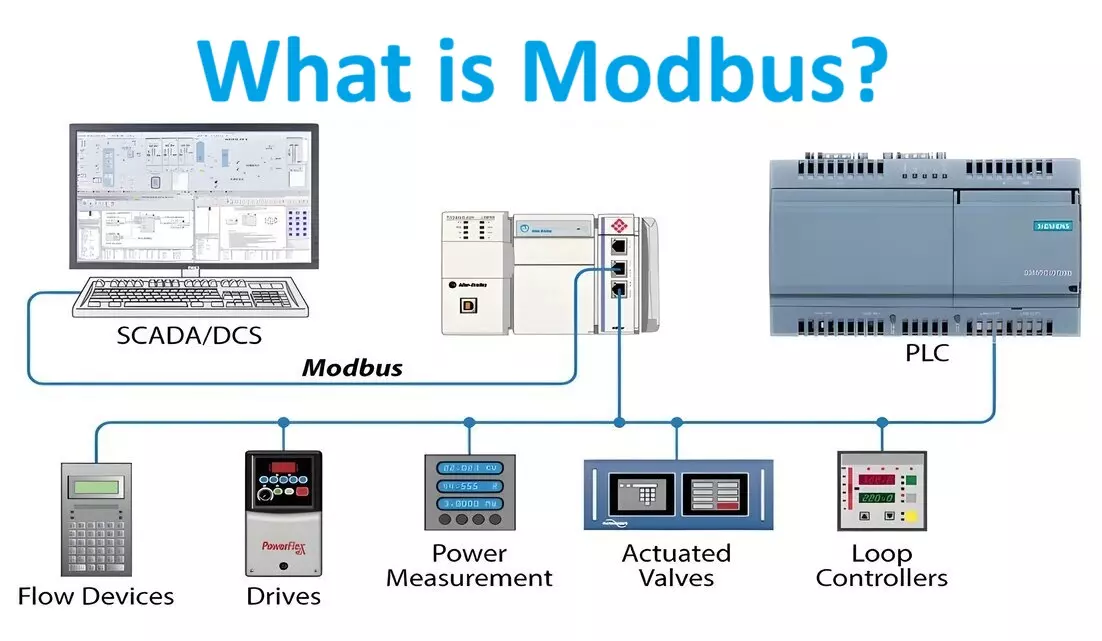

Modbus Communication Protocol is commonly used in industrial automation systems to exchange data between devices. It’s a simple and robust protocol, often used for connecting electronic devices such as programmable logic controllers (PLCs), remote terminal units (RTUs), sensors, and actuators.

Modbus Protocol History:

The Modbus communication protocol has a rich history dating back to the late 1970s. Here’s a brief overview of its evolution:

Development of Modbus by Modicon (1979):

Modbus was developed by Modicon (now part of Schneider Electric) in 1979 for its programmable logic controllers (PLCs). The aim was to create a simple and efficient communication protocol for industrial automation.

Modbus/RTU (Remote Terminal Unit):

Modbus/RTU, introduced in 1979, is the most common implementation. It uses binary coding for communication and includes error-checking using CRC (Cyclic Redundancy Check).

Modbus/ASCII:

Modbus/ASCII was introduced as an alternative to RTU. It uses ASCII characters for communication, making it more human-readable. Each 8-bit byte is represented as two ASCII characters.

Modbus/TCP (Transmission Control Protocol):

Modbus/TCP, developed later, allows Modbus communication over Ethernet networks. It utilizes the TCP/IP protocol suite, enabling communication between devices over standard Ethernet infrastructure.

Standardization (2004):

In 2004, the Modbus Organization (now Modbus-IDA Group) was formed to oversee the standardization and promotion of Modbus protocols. This organization ensures interoperability and maintains the Modbus specifications.

Expansion and Adoption:

Modbus has gained widespread adoption in various industries due to its simplicity, reliability, and interoperability. It’s used in industrial automation, building automation, energy management systems, and more.

Modbus Plus:

Modbus Plus is an extension of the original Modbus protocol, developed by Modicon. It adds features like token-passing and higher speed for larger-scale industrial networks.

Modbus Variants:

Over time, several variants and extensions of Modbus have been developed to address specific needs, such as Modbus/UDP (User Datagram Protocol) for lightweight communication and Modbus over Serial Line for specialized serial communication.

Despite being over four decades old, Modbus remains widely used and relevant in industrial automation due to its simplicity, versatility, and robustness. Its longevity can be attributed to its open nature, ease of implementation, and ongoing support from the industrial automation community.