Here is everything you need to know about high frequency PCBs, including what high frequency PCB is, features, materials used, and benefits of high frequency PCB.

Today, electronic devices are being developed with high frequency. Satellite devices and most information products move towards high frequency and high speed. Hence, more advanced PCBs are required, such as high-frequency PCBs.

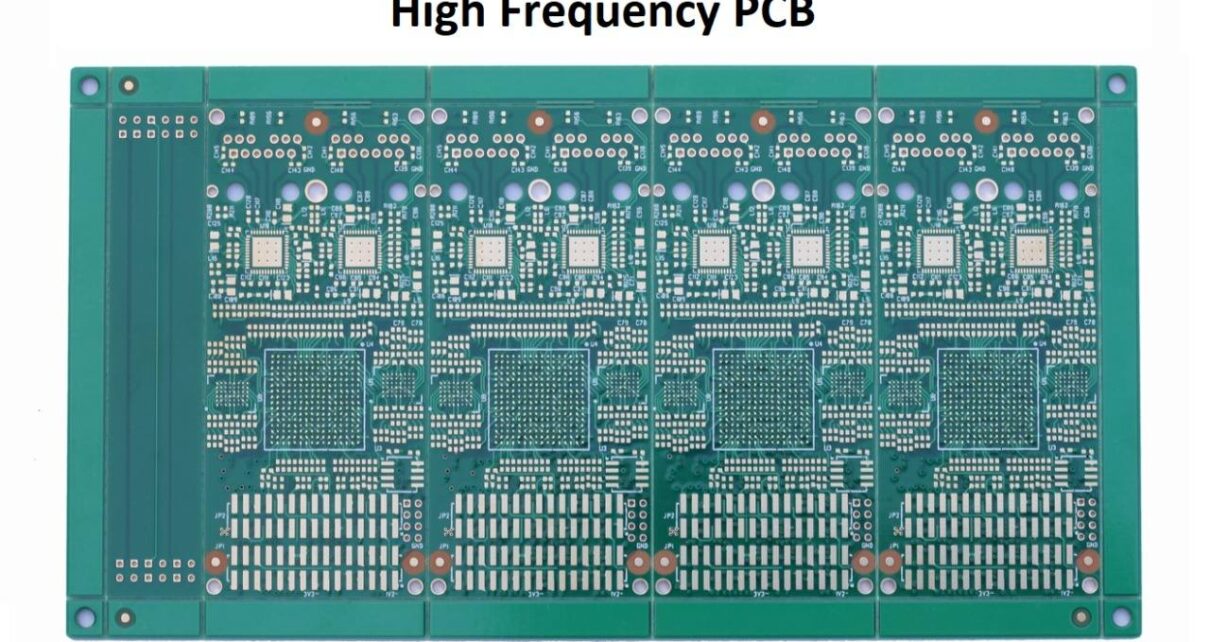

What is high frequency PCB?

High frequency printed circuit board is a particular printed circuit board with a very high electromagnetic frequency. Typically, a high frequency PCB is defined as a printed circuit board with a frequency of 1GHz or above.

Due to the complexity of most electronic devices, such as switches, they require faster signal flow rates. Hence, high transmission is needed. Happily, the invention of high frequency PCBs help when integrating signal requirements into these electronic components.

High frequency PCBs are mainly used due to their faster speed, high efficiency, constant dielectric properties, and lower attenuation.

Advantages of high frequency PCBs

1. High efficiency

One main advantage of high frequency PCBs is increased efficiency. A PCB with high efficiency is remarkable as it meets the heating requirements in most devices. In addition, it has excellent environmental protection.

2. High transmission speed

The transmission speed is essential for most electronic devices. Happily, another benefit of high frequency PCB is high transmission speed. This works well for sign transmission gadgets.

3. High-temperature control

Most of the applications of high frequency PCB are industries dealing with metal heating. So, since a high frequency PCB has high-temperature control, it is excellent for such sectors.

4. Strong tolerance

High frequency PCB is well designed to withstand harsh weather conditions. They are made of very low water-absorbing elements to tolerate the wet weather. Also, it has the advantage of moisture resistance, chemical corrosion resistance, and outstanding peeling strength.

Factors that influence a high frequency PCB design

Some of the factors that affect the design of high frequency design include:

When selecting materials for high-speed digital circuits, several factors affect the selection. For instance, they should have an excellent structural build-up.

Other factors that affect the design include product cost, heat sinking ability, signal loss tolerance, and the sandwich build materials.

Materials used for creating high frequency PCB

The performance of high-frequency printed circuit boards used in various applications relies on multiple materials. Some materials used include FR4 material, Rogers 4350B HF, Rogers RO3001, ARLON 85N, Rogers RO3003, Taconic TLX, and others.

Properties of High Frequency PCB

High frequency PCBs come with various properties. By understanding the properties, you will be in an excellent position to understand these circuit boards. They are known as high-frequency printed circuit boards because of their properties. Some of the properties of high frequency PCB include:

Dissipation factor

One property of high frequency PCBs is the low dissipation factor. The dissipation factor falls between 0.0019 and 0.025. The value ensures that the signal transmission rate is intact. The common dissipation factor is also beneficial since it enhances signal transmission. It helps to minimize signal loss.

Low and stable dielectric constant

Another critical property of high frequency PCB is that the dielectric constant is lower and stable. This is an essential property because it ensures frequency transmission. Also, it makes sure there is less signal delay. In addition, a lower dielectric constant improves frequency transmission.

Chemical resistance

A high frequency PCB can tolerate chemicals. They are well designed to survive any chemical attack when they are exposed to it. Hence, these circuit boards are less likely to corrode.

Low moisture absorption

These PCBs are designed to have a low rate of water absorption. The material used ensures there is low moisture absorption. Since the board cannot absorb moisture and other elements, it can easily withstand a humid environment.

Low dimensional stability

The other fundamental property of high frequency PCB is low dimensional properties. Irrespective of the temperature they are exposed to, they are able to maintain their shape and size. Their size does not change whether they are exposed to heat or cold climates; their size does not change.

Application of High Frequency PCBs

Due to their numerous benefits and outstanding properties, High Frequency PCBs have broad applications. Some of the main applications of high frequency PCBs are:

1. Medical applications

One area where high frequency PCBs are used is the medical sector. They are used in healthcare and personal monitors such as blood glucose monitors, heart rate monitors, and blood pressure monitors.

Also found in medical scanners such as X-ray, CT scanners, and MRI scanners. Other areas they are used include microscopes and photometers.

2. Industrial applications

Due to their outstanding properties, high frequency PCBs are also found in industrial devices. You can use them in electrical presses, electric drills, pressure measurement systems, 3d printing and other gadgets.

You can also use high frequency PCBs in power indicators of solar panels, inverters, and generators.

3. Advance communication applications

One benefit of high frequency PCBs is that they enable effective transmission of sound signals over a long distance. Hence, it allows clear communication no matter the distance.

Thus, they can be used for a number of advanced communication functions like amplification and filtering. You can also find them in mixing desks, microphones, booster stations, and receivers.

4. Radar System

High frequency PCBs are essential in most radar systems. In addition, they play a great role in the aviation and marine industries. Most devices in submarines, ships, and other marine machines use high frequency PCB. You can use them in aircraft for safe landing and navigation.

Final Word

High frequency PCBs provide outstanding features. This makes them suitable for a wide range of applications. In addition, they meet the demand for high-performance and high frequency applications. They have become popular in various sectors, including medical fields, automotive, industrial sectors, etc.